Maybe you’ve just bought an air impact wrench and want to ensure it lasts a long time. Or perhaps you’re just curious about the process. In either case, this blog post will walk you through the steps of how to clean and oil an air impact wrench. It’s a pretty simple and effective process, but if you’re unfamiliar with it, read on! We’ll start with the basics.

Why is it essential to oil an air impact wrench?

However, like any other tool, an air impact wrench requires regular maintenance to function correctly. An air impact wrench can be used for a variety of applications, from auto repair to construction.

When used correctly, an air impact wrench can save time and effort by quickly loosening or tightening nuts and bolts. One crucial step in maintaining an air impact wrench is to oil it regularly. Here are a few benefits of oiling air impact wrench-

- It helps to prevent rust and corrosion, which can damage the tool over time.

- Oiling an air impact wrench helps to keep the internal parts lubricated and working smoothly.

- Regular oiling helps extend the tool’s life, saving you money in the long run.

In addition, So if you want to keep your air impact wrench in top condition, make sure to give it a few drops of oil regularly.

What you will need

- Soft cleaning cloth and brush

- Screwdriver

- Soapy water

- Bowl

- Lubricating oil WD-40

Which parts of an air impact wrench need to be lubricated?

The air impact wrench is a relatively simple device, and it is important to ensure that all of its parts are properly lubricated. Otherwise, friction can quickly cause wear and tear, potentially damaging or even breaking.

The piston and cylinder are the most critical parts of an air impact wrench to lubricate. This will help you to decrease friction and maintain optimal performance.

In addition, it is also a good idea to lubricate the anvil, trigger, and sleeve assembly. Doing so will help prolong the tool’s life and keep it running smoothly.

How to clean and oil an air impact wrench?

How to clean an air impact wrench

Air impact wrenches are an excellent tool for anyone who works with vehicles. They are powerful and can quickly loosen or tighten lug nuts. But like any tool, they must be cleaned and maintained to prevent rust and wear.

Before oiling, it’s crucial to clean the air impact wrench properly. Cleaning an air impact wrench is a pretty straightforward process. Your tool will be clean and ready to use in just a few minutes!

- Unplug the impact wrench from the air compressor.

- Take the air impact wrench apart by unscrewing the bolts that hold it together.

- Once it’s disassembled, soak all of the pieces in soapy water for a few minutes. Then Use a brush and soft cloth to remove any dirt or debris from the tool.

- In this step, use a soft dry cloth to wipe down the body of the wrench. You should be careful not to get any oil or grease on the floor.

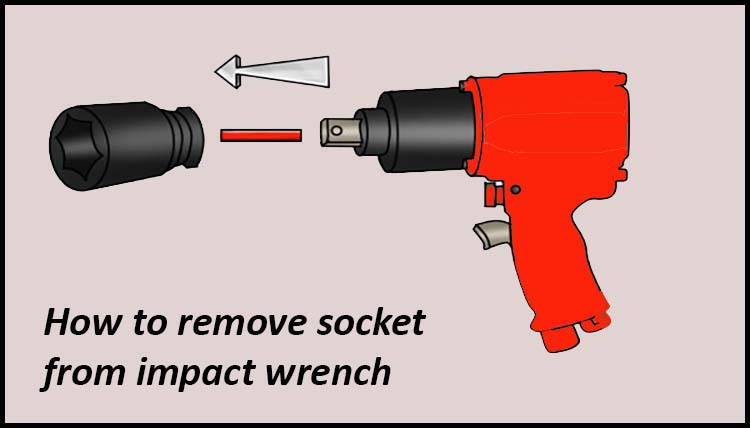

- Remove the socket from the chuck and inspect it for wear or damage. Clean it properly and replace the socket with a new one if necessary.

- Use a wrench to unscrew the anvil from the body of the wrench. Clean the anvil and inspect the anvil for wear or damage.

- You can clean any dirt or debris that might have gathered in the chuck using a brush; always be careful not to damage the teeth on the jaws.

- Screw the anvil back into place and reattach the socket to the chuck.

That’s it, just follow these eight steps and clean your air impact wrench more than ever before.

How to oil air impact wrench

Nothing is more frustrating than trying to loosen a stubborn bolt and being unable to get the wrench to grip. It can be infuriating, especially if the bolt needs to come out quickly. But with the help of an air impact wrench, this job can be done quickly and easily.

Oiling an impact wrench will provide you with excellent performance. Here’s a step-by-step guide to oiling:

Step-1

If the wrench is connected to an air compressor, disconnect the air supply from the wrench and turn off the compressor.

Step-2

Next, remove the housing from the wrench. This will help you to give access to the internal components of the tool.

Step-3

Using a clean, soft cloth, wipe away any dirt or debris that has been collected in the reservoir. (which we mentioned in detail earlier)

Step-4

Locate the oil reservoir and unscrew the cap. Often, the reservoir will be located near the air inlet.

Step-5

Using a funnel, add oil to the reservoir until it’s full. Be sure to use a high-quality oil specifically designed for air tools.

Step-6

Also, oil all the moving parts on the wrench, including the piston, before reattaching it to the air compressor.

Step-7

Replace the reservoir cap and screw it tight. You don’t want any oil leaking out while the tool is in use.

Step-8

Finally, reattach the housing and reconnect the air supply. Once you’ve done this, your air impact wrench should be properly lubricated and ready for use.

You may also like: What size impact wrench do I need for my work?

Tips and tricks when using an air impact wrench to get good performance

An air impact wrench is a powerful tool that can quickly work large bolts and screws. However, it is vital to use the tool correctly to achieve optimal performance. Here are a few tips and tricks:

- Before using the wrench, be sure to read the manufacturer’s instructions carefully. This will help you understand how the tool works and how to operate it properly.

- When attaching the air hose to the wrench, use a quick-connect coupling. This will allow you to quickly disconnect the hose if necessary.

- Always use an impact-rated socket with the wrench to avoid damage to the work surface.

- Always start with the lowest torque setting when using the wrench. Once you have loosened the bolt or screw, you can increase the speed if necessary.

- Finally, when you are finished using the wrench, disconnect the air hose and release any residual pressure before storing the tool.

Just follow these simple suggestions to ensure that your air impact wrench always performs at its best.

FAQS

What kind of oil do you use for an air impact wrench?

When it comes to lubricating an air impact wrench, there are a few things to keep in mind.

- The type of oil you use can significantly impact performance. For example, lighter oils like mineral or synthetic oils may not provide the same level of protection as heavier oils like grease.

- It’s essential to ensure that the oil you’re using is compatible with your air impact wrench material.

- Using oil that contains petroleum can damage plastics and rubbers.

- Finally, be sure to check your air impact wrench’s manual to see what kind of oil they recommend.

How much oil do I put in an air impact wrench?

Air impact wrenches are essential for many industries, from automotive to construction. They provide high torque output with minimal effort, making them ideal for loosening and tightening bolts. When it comes to maintaining an air impact wrench, it is important to pay attention to the amount of oil used. Too much oil can cause the wrench to slip, while too little can damage the internal components. The general rule is to add 1-2 drops of oil every 30 seconds of use. However, this may vary depending on the specific model of a wrench being used.

How often should the air impact wrench be oiled?

An air impact wrench is ideal for use in situations where traditional hand tools would be ineffective. An impact wrench typically has two parts: an anvil and a hammer. The anvil is the part that strikes the fastener, while the hammer transfers energy from the motor to the anvil.

Impact wrenches require regular maintenance to ensure optimal performance. One of the most critical maintenance tasks is regularly oiling the anvil and hammer. This helps to keep the components lubricated and prevents them from overheating. Depending on the make and model of your impact wrench, you may need to oil it every few weeks or months. Consult your owner’s manual for specific instructions.

What kind of grease for impact wrench?

Impact wrenches are powerful tools that can be used to loosen or tighten large bolts. Impact wrenches work by delivering a high-torque impact, which can quickly break through rust and buildup. For this reason, a high-quality and right-type lubricant is essential.

Many impact wrenches come with a recommended lubricant. But there are a few factors to keep in mind when choosing a grease for your impact wrench.

First, it should contain a high class of resistance to wear and tear.

Second, it should be able to withstand high temperatures.

Finally, it should have low friction properties to prevent the tool from overheating.

By selecting the right lubricant, you can ensure that your impact wrench works efficiently and lasts for many years.

Conclusion

By reading the above steps, you will be able to oil your air impact wrench efficiently and effectively. It is wise to check the owner’s manual for specific instructions on how to oil your model. Regular maintenance will help keep your air impact wrench working correctly for years. Do you have any tips on how to maintain an air impact wrench? Please share your helpful information with us in the comments below!

See also: